Large dimension Canbar Wood Stave Tanks are used widely by the Pulp and Paper, Mining and other industries. Such tanks are often 50 ft. (15m) and more in diameter, with heights frequentlyin excess of 70 ft. (20m). These tanks are used both to contain in-process liquids and often some difficult to handle (high/low pH, etc.) chemicals. These tanks typically are located out-of-doors in climates ranging from tropical to northern Canada.

At the opposite extreme smaller dimension Canbar Wood Stave Tanks are widely used in water treatment plants and other indoor liquid chemical containment applications.

Most large tanks for Pulp and paper, Mining, etc. applications have no liner. The tank wood wall and floor absorbs water and expands against the outside steel restraining bands, to create a watertight tank.

Other tanks are lined on the inside with PVC liners. Combining the stretchability of flexible PVC liners with the time proven structural strength, durability and corrosion resistance of wood, Canbar Wood Stave Tanks are the ideal solution to the challenge of safely storing aggressive chemicals.

Because the liner is free forming and flexible it conforms with ease to the alternating stresses caused by fluctuating chemical levels in the tank. PVC has good tensile, and elongation strength, as well as tear and chemical resistance. Its ability to withstand heat and cold is enhanced by the insu-lating and anti-corrosion properties of wood, providing a stable environment.

Do you need to install a large tank inside an existing building? Canbar Wood Stave Tanks are prefabricated and then assembled on site.

The wood staves, PVC covered steel bands and the PVC liner will fit through normal man-door openings. This allows for installation of a sizeable tank inside an existing facility, without the need to carry out major building reconstruction.

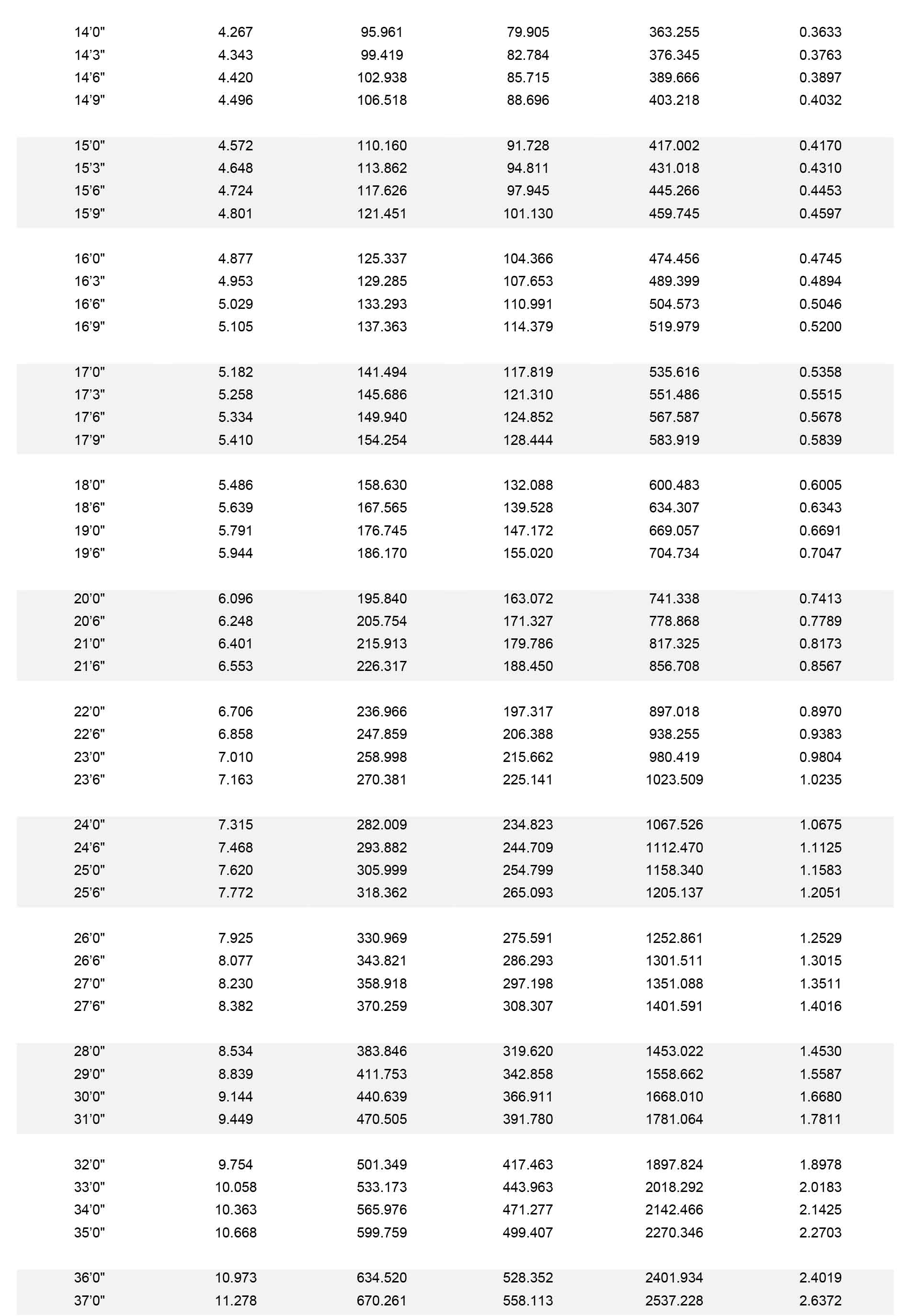

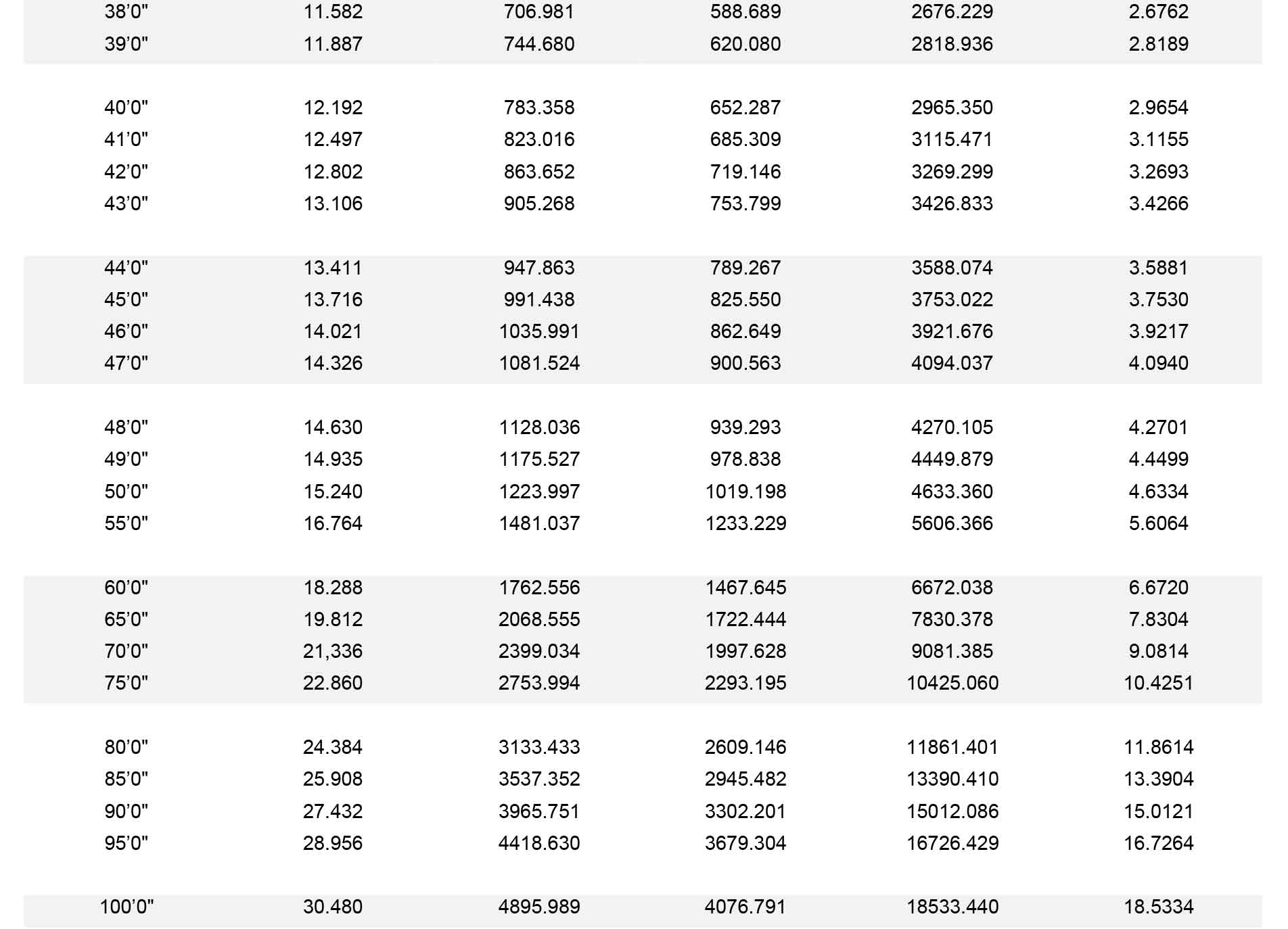

Canbar Wood Stave Tanks can be custom designed to fit your specific needs. They are available in a wide range of capacities, from 5,000 litres (1300 U.S. Gal.) to 5 million litres (1.4 million U.S. Gal.) and more. Pipe connections and flow control appurtenances are easily accommodated; the liner can project through the wall and fittings to the flanged connection, providing a continuous barrier.

Marrying the chemical resistance of PVC membrane liners with the corrosion resistance of wood makes Canbar Wood Stave Tanks doubly safe. Aggressive chemicals with cycling levels have been stored in Canbar Wood Stave Tanks for decades without failure. The natural resistance of wood to the corrosive action of chemicals, used in water treatment facilities, makes it a safe, secure, second line of defense for the PVC liner. Should the liner ever be pierced, the Wood Stave Tank provides non-catastrophic containment until the liner can be repaired or replaced. PVC membrane lined Canbar Wood Stave Tanks are containment you can count on.

When dealing with hostile elements and varying temperatures Canbar Wood Stave Tanks are the ideal solution. The high insulation factor of wood elimi-nates the need for expensive insulation required by other materials. In the case of widely fluctuating temperatures, in particular extreme sub zero conditions, electric strip heating can be used to maintain required tempera-tures.

Consulting and municipal engineers across Canada and the United States recommend Canbar Wood Stave Tanks. Their confidence is built on Canbar’s record of dependability, durability and the wide range of chemicals that Wood Stave Tanks can safely contain, including the following: Liquid Alum, Sodium Hydroxide, Hydrochloric Acid, Sulphuric Acid, Sodium Hypochlorite, Hydro-fluosilisic Acid, Ferric Chloride and Aqua Ammonia.

A – PVC Covered Steel Bands

B – Epoxy Coated Lugs

C – Optional Access Ladder

D – Entry Manway

(600mm x 600mm)

E – Plywood Cover

F – PVC Compression Fittings

G – Cover Support Beams

H – FRP Contoured Fittings

I – Wood Staves

J – Flexible PVC Liner

K – Bottom Head

L – Support Joists

M – Liquid Level Indicator